Concrete Batching Plant Price: A Comprehensive Guide

This guide provides a detailed overview of concrete batching plant price factors, helping you understand the costs involved in purchasing and operating a plant. We’ll explore various types of plants, influencing factors on pricing, and provide resources for finding reliable suppliers like Taian Yueshou Mixing Equipment Co.,Ltd. to assist you in your purchasing decision. Learn about different capacity options, technological advancements, and the overall return on investment for concrete batching plants.

Factors Affecting Concrete Batching Plant Price

Plant Capacity and Type

The price of a concrete batching plant is heavily influenced by its capacity. Smaller, stationary plants designed for smaller projects will naturally cost less than large, mobile plants capable of handling massive construction projects. The type of plant (e.g., stationary, mobile, central-mix, ready-mix) also plays a crucial role. Mobile plants, offering greater flexibility, typically command a higher concrete batching plant price. Central-mix plants, known for their high production capacity, represent a significant investment.

Technology and Features

Modern concrete batching plants often incorporate advanced technologies like automated control systems, digital weighing systems, and sophisticated software for optimized production. These features enhance efficiency and precision, but also contribute to a higher concrete batching plant price. Consider features such as dust suppression systems, concrete quality control systems, and remote monitoring capabilities. These add to the initial cost but can provide significant long-term benefits.

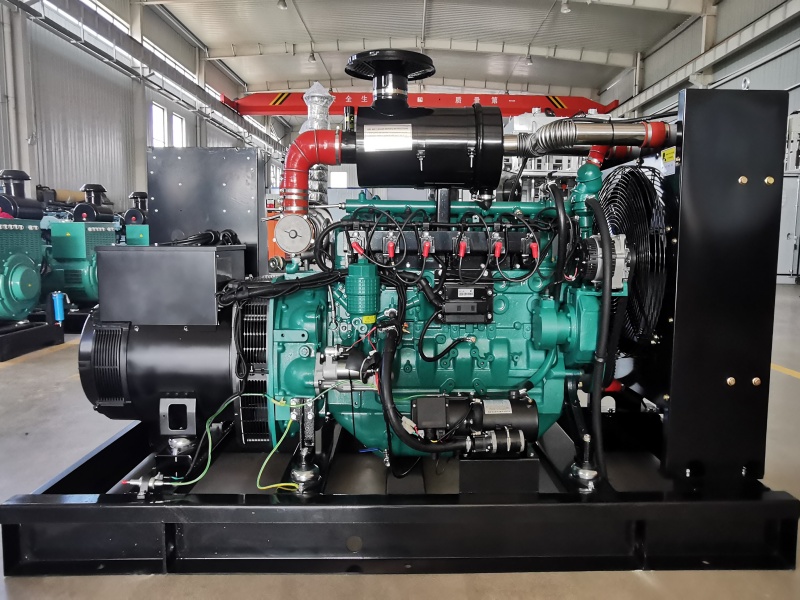

Components and Materials

The quality of components used in the construction of the plant directly impacts the concrete batching plant price. High-quality, durable components lead to a higher upfront cost but promise longevity and reduced maintenance expenses. Factors such as the material used in the construction of the plant (e.g., steel grade, type of concrete mixer) influence the final cost.

Manufacturer and Supplier

Prices vary significantly depending on the manufacturer and supplier. Research different companies, compare their offerings and reputation, and check customer reviews before making a purchase. Working with a reputable supplier, such as Taian Yueshou Mixing Equipment Co.,Ltd., ensures you receive quality equipment and after-sales support.

Location and Transportation

The cost of transporting the plant to your location can significantly add to the overall concrete batching plant price. This is especially true for larger, more complex plants requiring specialized transport. Consider the distance from the manufacturer and any associated permits or fees for transportation.

Estimating the Concrete Batching Plant Price

Obtaining accurate pricing requires engaging with multiple concrete batching plant manufacturers and suppliers. Request detailed quotes that clearly outline all included components and services. Be sure to specify your required capacity, desired features, and any customizations you need. Don’t hesitate to negotiate and compare quotes to secure the best possible concrete batching plant price.

Return on Investment (ROI)

The initial concrete batching plant price is a significant investment, but the potential return on investment can be substantial, especially for large-scale projects. Factors influencing ROI include plant utilization rate, production efficiency, and the overall demand for concrete in your region. Careful planning and thorough market analysis are crucial for maximizing returns.

Choosing the Right Concrete Batching Plant

Selecting the appropriate plant involves careful consideration of your project requirements, budget, and long-term operational goals. Consulting with industry experts and reviewing case studies can provide valuable insights into the suitability of different plant types and sizes.

| Plant Type | Approximate Price Range (USD) | Capacity |

|---|---|---|

| Small Stationary | $50,000 – $150,000 | Low to Medium |

| Medium Mobile | $150,000 – $300,000 | Medium to High |

| Large Central-Mix | $300,000+ | High |

Note: Price ranges are estimates and can vary significantly based on the factors discussed above. Consult with manufacturers for accurate pricing.