Find the Perfect Small Concrete Plant for Sale

This comprehensive guide helps you find the ideal small concrete plant for sale, covering factors like capacity, features, pricing, and maintenance. We’ll explore various types of plants, helping you make an informed decision based on your specific needs and budget. Learn about key considerations before purchasing and where to find reputable suppliers.

Understanding Your Needs: Choosing the Right Small Concrete Plant

Capacity and Output

The first step is determining your required concrete production capacity. Consider your project size, frequency of use, and future expansion plans. Small concrete plants range in output, from small-scale batching plants suitable for residential projects to larger units capable of handling commercial-scale work. Factors like mix design and aggregate type also influence output.

Types of Small Concrete Plants

Several types of small concrete plants are available, each with its own advantages and disadvantages. These include:

- Mobile Concrete Batching Plants: Highly portable and ideal for projects on various sites.

- Stationary Concrete Batching Plants: Offer higher capacity and are suitable for long-term use at a fixed location.

- Mini Concrete Plants: Compact and economical solutions for small-scale projects.

Researching the specific features of each type will help you determine which best aligns with your project demands. Remember to consider the space available for setup and operation.

Essential Features to Consider

When selecting a small concrete plant for sale, pay attention to features such as:

- Automated controls for ease of operation and consistent mix quality.

- Durable construction materials for longevity and reduced maintenance.

- Efficient mixing systems to minimize downtime and maximize productivity.

- Safety features to protect operators and comply with regulations.

- Ease of maintenance and access to spare parts.

Where to Find Reputable Suppliers of Small Concrete Plants

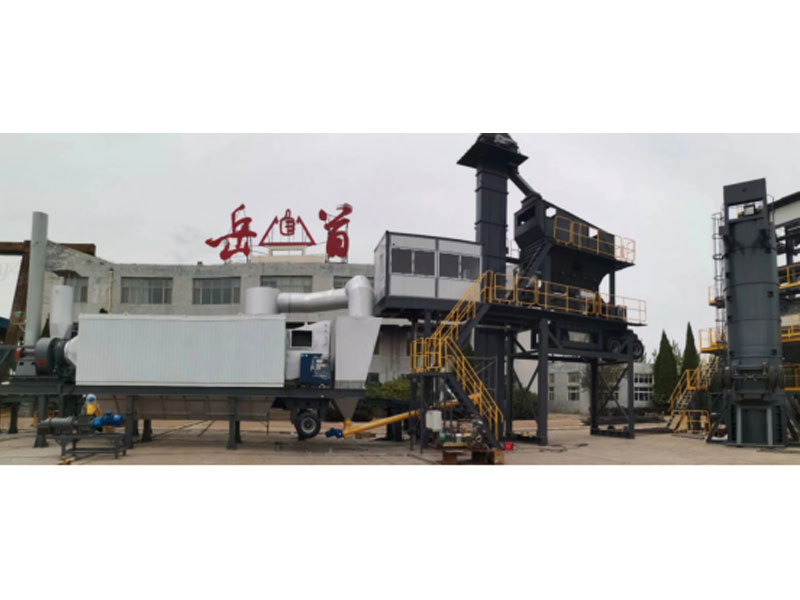

Finding a reliable supplier is crucial for a successful purchase. Thoroughly research potential suppliers, checking for online reviews, testimonials, and industry certifications. Consider contacting multiple suppliers to compare prices, features, and after-sales service. Look for suppliers with a proven track record and a strong reputation for customer satisfaction. One such supplier you may wish to explore is Taian Yueshou Mixing Equipment Co.,Ltd., a leading manufacturer of high-quality mixing equipment. They offer various options for small concrete plants to meet different project needs.

Budgeting and Financing Your Purchase

The cost of a small concrete plant varies depending on size, features, and supplier. Develop a detailed budget that includes the purchase price, transportation, installation, and any necessary permits. Explore financing options if needed, comparing interest rates and repayment terms from different lenders. Remember to factor in ongoing maintenance and operational costs.

Maintenance and Operational Costs

Regular maintenance is crucial for the long-term performance and lifespan of your small concrete plant. Develop a preventative maintenance schedule to minimize downtime and reduce repair costs. This includes regular inspections, cleaning, and lubrication of key components. Factor in the cost of spare parts and potential repairs when budgeting.

Comparison Table of Small Concrete Plant Features

| Feature | Mobile Plant | Stationary Plant | Mini Plant |

|---|---|---|---|

| Portability | High | Low | High |

| Capacity | Medium | High | Low |

| Cost | Medium | High | Low |

Remember to always prioritize safety and comply with all relevant regulations when operating a small concrete plant. This guide is for informational purposes only and should not substitute professional advice.