Choosing the Right Stationary Concrete Batching Plant

This comprehensive guide helps you understand the key factors to consider when selecting a stationary concrete batching plant. We’ll explore different types, capacities, features, and considerations to ensure you make the best investment for your concrete production needs. This guide covers everything from initial setup to ongoing maintenance, empowering you to make an informed decision.

Understanding Stationary Concrete Batching Plants

What is a Stationary Concrete Batching Plant?

A stationary concrete batching plant is a fixed, large-scale concrete production system designed for high-volume, continuous operation. Unlike mobile plants, these are permanently installed at a specific location, often within a pre-fabricated building or designated area. They are ideal for large-scale construction projects, ready-mix concrete suppliers, and other applications requiring consistent, high-quality concrete output. Key components include aggregate bins, weighing systems, mixers (typically twin-shaft or pan mixers), cement silos, water tanks, and control systems. The size and configuration vary greatly depending on the required production capacity and specific project demands. They offer significant advantages in terms of efficiency, production capacity, and overall cost-effectiveness over time compared to smaller mobile units.

Types of Stationary Concrete Batching Plants

There are several types of stationary concrete batching plants, each with its own advantages and disadvantages. The choice depends on factors like production capacity, budget, and specific project requirements. Common types include:

- Pre-fabricated Plants: These arrive largely assembled, simplifying installation and reducing setup time. They are excellent for projects requiring quicker deployment.

- Custom-Built Plants: These offer greater flexibility in design and component selection to meet highly specific requirements. However, they typically require longer lead times and potentially higher costs.

- Dry Batching Plants: These mix dry ingredients before adding water, offering better control over the mix design and often resulting in higher-quality concrete.

- Wet Batching Plants: These mix all ingredients simultaneously, including water, which is generally a simpler process but may offer slightly less control over the precise composition.

Factors to Consider When Choosing a Stationary Concrete Batching Plant

Capacity and Production Requirements

The most crucial factor is determining your required concrete production capacity. This depends on the size and scope of your projects. Consider peak demand and future growth potential when assessing capacity needs. Overestimating or underestimating your needs can impact profitability and project timelines. Plants are available in various capacities, measured in cubic meters per hour (m3/h).

Budget and Return on Investment (ROI)

Stationary concrete batching plants represent a significant investment. Thoroughly evaluate different models and suppliers, comparing initial costs, maintenance expenses, and potential return on investment. Consider the long-term operational costs, including energy consumption and maintenance schedules.

Features and Technology

Modern plants incorporate advanced automation, control systems, and monitoring features to optimize efficiency and minimize waste. Explore options such as automated ingredient dispensing, real-time monitoring systems, and integrated software for better control and tracking of your production process. Look for features that enhance safety and minimize environmental impact.

Maintenance and Support

Reliable after-sales service and readily available parts are crucial for minimizing downtime and ensuring consistent operation. Investigate the manufacturer’s reputation and the availability of technical support. A robust maintenance plan should be part of your overall investment strategy.

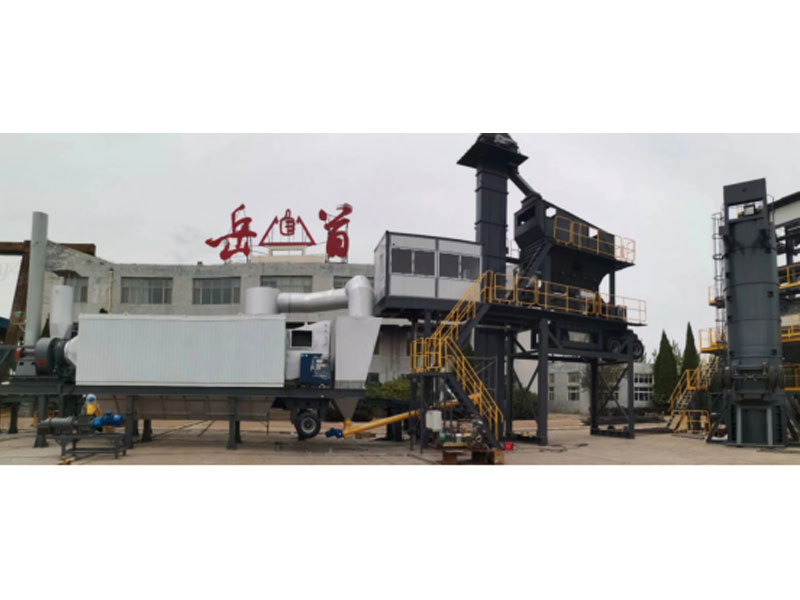

Choosing the Right Supplier

Selecting a reputable supplier is paramount. Consider their experience, track record, and commitment to customer support. Look for companies offering comprehensive solutions, including design, installation, training, and ongoing maintenance services. Companies like Taian Yueshou Mixing Equipment Co.,Ltd are known for their high-quality stationary concrete batching plants and excellent customer support. Their expertise in the field ensures that their equipment meets the highest standards of performance and reliability.

Conclusion

Investing in the right stationary concrete batching plant is a significant decision that impacts productivity, profitability, and long-term success. By carefully considering the factors outlined in this guide, you can choose a system that meets your specific needs and delivers exceptional performance for years to come.

table { width: 700px; margin: 20px auto; border-collapse: collapse;}th, td { border: 1px solid #ddd; padding: 8px; text-align: left;}th { background-color: #f2f2f2;}