Finding the Right MDC Ready Mix Concrete Plant for Your Needs

This guide provides comprehensive information on selecting the ideal MDC ready mix concrete plant, covering factors like capacity, automation, and environmental impact. We’ll explore different types of plants, crucial considerations for purchase, and resources to aid your decision-making process. Learn how to optimize your concrete production with the right equipment and infrastructure.

Understanding MDC Ready Mix Concrete Plants

What is an MDC Ready Mix Concrete Plant?

An MDC ready mix concrete plant refers to a facility designed for the efficient production of ready-mix concrete. MDC likely refers to a specific manufacturer or type of plant, but the core function remains the same: combining cement, aggregates, water, and admixtures to create concrete that’s ready for immediate use at construction sites. These plants vary significantly in size, capacity, and level of automation, catering to different project scales and demands. The choice depends heavily on factors like the volume of concrete required, the types of projects undertaken, and budgetary considerations.

Types of MDC Ready Mix Concrete Plants

Several types of MDC ready mix concrete plants exist, each with its own advantages and disadvantages. These often include stationary, mobile, and portable options. Stationary plants are large-scale installations ideal for consistently high-volume production. Mobile plants offer flexibility for projects in various locations, while portable plants are smaller and suitable for smaller-scale operations. The selection depends greatly on project specifics and long-term production goals.

Key Factors to Consider When Choosing a MDC Ready Mix Concrete Plant

Production Capacity and Efficiency

The first crucial consideration is the plant’s production capacity. This must align with your projected concrete needs. A plant that’s too small will limit your output, while an oversized plant represents unnecessary investment. Efficiency is equally important, considering factors like batching speed, mixing time, and overall operational flow. Look for plants with features that optimize these aspects, potentially including automated systems and advanced control technology.

Automation and Technology

Modern MDC ready mix concrete plants often incorporate advanced automation and technology. This can encompass automated batching systems, computer-aided controls, and even remote monitoring capabilities. Automation improves accuracy, consistency, and efficiency, minimizing manual labor and potential errors. Consider the level of automation that aligns with your budget and technical expertise.

Environmental Considerations

Environmental impact is a growing concern in the construction industry. Look for plants designed with sustainability in mind, such as those featuring dust suppression systems, water recycling capabilities, and energy-efficient components. Consider the long-term environmental implications of your choice, and prioritize plants with a demonstrable commitment to sustainability.

Finding the Right Supplier

Selecting a reliable supplier is paramount. Research potential suppliers thoroughly, evaluating their reputation, track record, and customer support. Check for certifications, warranties, and after-sales service options. A reputable supplier will offer guidance throughout the selection and installation process and provide ongoing technical support.

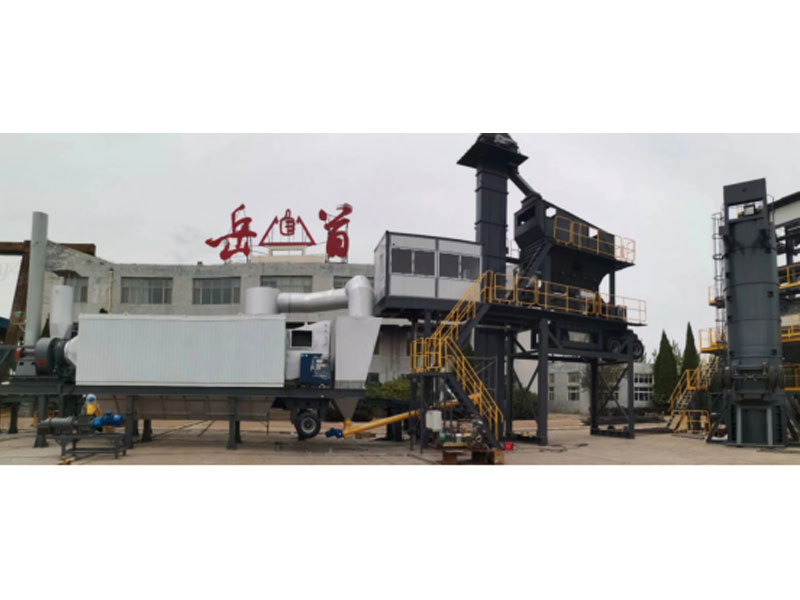

For high-quality mixing equipment, consider Taian Yueshou Mixing Equipment Co.,Ltd. They offer a range of solutions for various concrete production needs.

Conclusion

Choosing the right MDC ready mix concrete plant is a significant decision with long-term implications for your business. Careful consideration of production capacity, automation, environmental factors, and supplier reliability is crucial for ensuring a successful outcome. By carefully weighing these aspects, you can select a plant that optimizes efficiency, minimizes costs, and meets your specific requirements.