Noor Al Sahara Asphalt Plant: A Comprehensive GuideNoor Al Sahara asphalt plants are crucial for infrastructure development in the region. This guide provides a detailed overview of their operations, technologies, and the importance of choosing the right equipment for optimal performance. We’ll explore key aspects impacting efficiency and sustainability.

Noor Al Sahara Asphalt Plant: A Deep Dive

The demand for high-quality asphalt in regions like Noor Al Sahara necessitates efficient and reliable asphalt plants. Understanding the intricacies of these plants is critical for successful infrastructure projects. This guide delves into the key aspects of Noor Al Sahara asphalt plant operations, addressing various factors influencing their effectiveness.

Types of Asphalt Plants Used in Noor Al Sahara

Several types of asphalt plants are employed in the Noor Al Sahara region, each with its own advantages and disadvantages. The choice often depends on project scale, budget, and specific requirements.

Batch Plants

Batch plants are known for their simplicity and relatively lower initial investment. They are suitable for smaller projects with fluctuating demands. However, their production capacity is typically lower compared to continuous plants.

Continuous Plants

Continuous plants offer higher production capacity and greater efficiency for large-scale projects. They provide consistent asphalt output, making them ideal for long-term infrastructure developments. However, the initial investment is significantly higher.

Drum Mix Plants

Drum mix plants are a popular choice due to their ability to produce high-quality asphalt with excellent uniformity. They are highly efficient and can handle various aggregate types. Maintenance requirements are a factor to consider.

Key Considerations When Selecting a Noor Al Sahara Asphalt Plant

Selecting the right Noor Al Sahara asphalt plant is crucial for project success. Several factors influence this decision:

Production Capacity

The required production capacity directly impacts the type of plant needed. A larger project demands a higher capacity plant, typically a continuous plant.

Quality Control

Maintaining consistent asphalt quality is paramount. Modern plants incorporate advanced technology to ensure precise mixing and temperature control.

Environmental Impact

Minimizing environmental impact is crucial. Choosing a plant with efficient emissions control systems is vital for sustainability. Consider plants that meet regional environmental regulations.

Maintenance and Operational Costs

Long-term operational costs, including maintenance and energy consumption, should be carefully evaluated. Regular maintenance is key for extended lifespan and optimal performance.

The Role of Advanced Technology in Modern Asphalt Plants

Modern Noor Al Sahara asphalt plants increasingly utilize advanced technologies to enhance efficiency, quality control, and sustainability. These include:

Automated Control Systems

Automated systems optimize the mixing process, ensuring consistent asphalt quality and minimizing waste.

Emissions Control Technologies

Modern plants employ sophisticated emissions control systems to reduce harmful pollutants and meet environmental standards.

Energy-Efficient Designs

Energy-efficient designs reduce operational costs and minimize the plant’s environmental footprint.

Finding Reliable Suppliers for Noor Al Sahara Asphalt Plants

Choosing a reliable supplier is essential for acquiring a high-quality and efficient asphalt plant. Thorough research is crucial to ensure the supplier’s reputation and technical expertise.

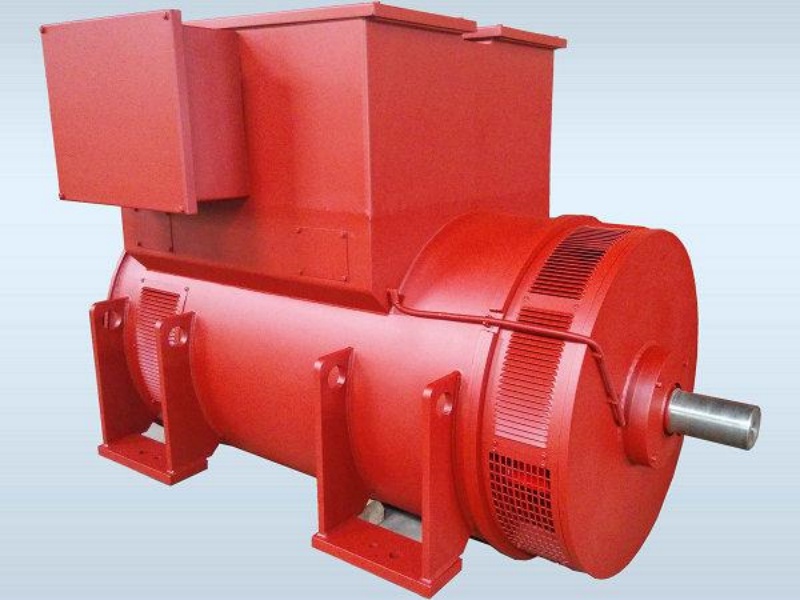

For high-quality mixing equipment, consider exploring options from reputable manufacturers like Taian Yueshou Mixing Equipment Co.,Ltd., a leading provider of innovative mixing solutions for various industries.

Conclusion

The selection and operation of a Noor Al Sahara asphalt plant require careful consideration of various factors. Choosing the right plant type, technology, and supplier ensures optimal performance, efficiency, and sustainability for infrastructure projects in the region. Investing in advanced technology and prioritizing quality control contributes to long-term success.